Beauty and skin care is one of the daily necessities for both men and women in modern life. It is believed that everyone’s dresser will have some beauty and skin care bottles and jars. With so many skin care products, you may not know how these brand cosmetics are produced. Let’s follow TopSail Automation to look at the things in the brand cosmetics production line.

First, make a brief introduction to the production line of cosmetics and skin care products

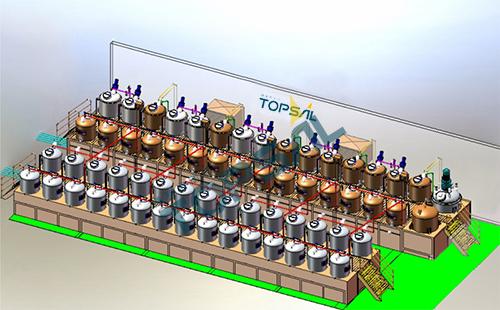

Skin care cream production line

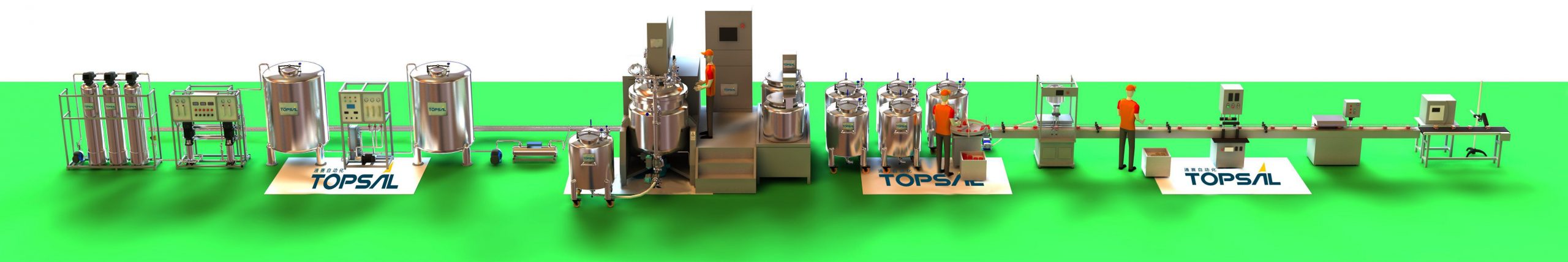

For the production line of skin care cream products, the first step is to treat the water required for production. There are corresponding standards for the production of cosmetics. At this time, a water treatment equipment is required, mainly for the purpose of impurities, sediment, solid dissolved substances, organic substances, alternating substances, microorganisms, bacterial impurities, etc. in the effluent.

TopSail Automatic water treatment equipment

The next one is the vacuum homogenizing emulsifier, which is used to make products with paste, emulsion and other textures. Under the vacuum state, the materials are quickly and evenly distributed into another continuous phase by using the high shear emulsifier, which uses the strong kinetic energy brought by the machinery to make the materials withstand hundreds of thousands of hydraulic shears per minute in the narrow gap between the stator and rotor. Centrifugal extrusion, impact, tear and other comprehensive effects can instantly and evenly disperse and emulsify, and finally obtain bubble free, delicate and stable high-quality products after high-frequency cycling.

TopSail Automatic Vacuum Homogenization Emulsifier

The products can be transported to the filling equipment after the stainless steel tank is made. There are many kinds of filling equipment, including semi-automatic, full brake and other options. After filling, the automatic capping machine is integrated with the filling machine for many times, so that it is convenient to operate and save time. Finally, after filling, the brand information is pasted on the labeling machine, so that the product is finished and can be packaged and shipped.

中文站

中文站 En

En